Underwater Hull Cleaning and Propeller Polishing by Meera Marine

Meera Marine provides professional underwater hull cleaning and propeller polishing services to enhance vessel performance, reduce fuel consumption, and maintain compliance with environmental and operational standards. These services are carried out by certified divers and experienced underwater technicians using specialized equipment and procedures.

- Pre-Operation Planning and Safety Measures

A thorough pre-job briefing is conducted, including site risk assessment and diver safety protocols.

Necessary permits are obtained, and coordination is done with port authorities and ship staff.

The area around the ship is secured and marked for underwater operations. - Hull Cleaning Procedure

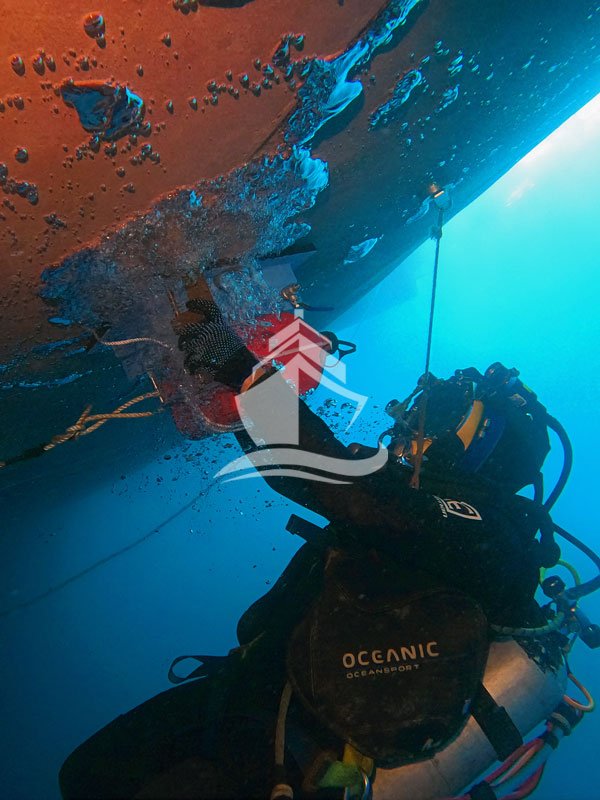

Divers inspect the hull to assess the level and type of marine growth.

Cleaning is performed using hydraulically driven or pneumatic rotating brush machines, carefully selected based on hull coating type (e.g., SPC, foul release). Soft brushes are used to avoid damaging antifouling coatings.

Cleaning is done systematically in sections, covering flat bottom, vertical sides, bilge keels, sea chests, and gratings. - Propeller Polishing Procedure

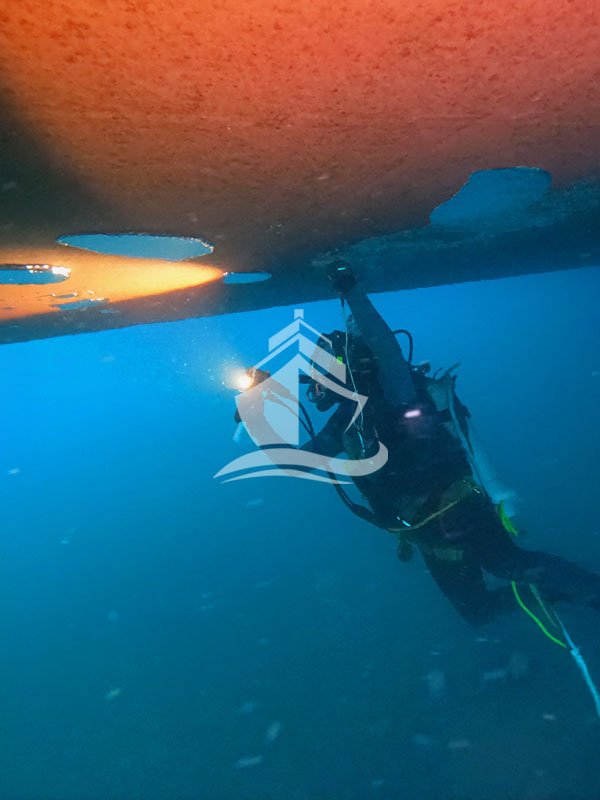

Divers use rotary polishing tools fitted with abrasive discs or polishing pads.

The propeller blades are cleaned of marine growth and polished to a smooth, mirror-like finish.

Special care is taken to remove any cavitation damage marks or minor surface imperfections.

Final surface roughness is checked using underwater profilometers, if required. - Post-Cleaning Inspection and Reporting

Video and photographic documentation is provided for before-and-after comparisons.

Detailed reports include diver observations, work carried out, and any recommendations for further maintenance.

Environmental guidelines are strictly followed to minimize seabed disturbance and waste disposal.

Meera Marine's underwater services ensure vessels maintain optimal hydrodynamic performance, reducing fuel costs and emissions while avoiding dry dock delays.