Motor and Alternator Rewinding by Meera Marine

Meera Marine offers expert motor and alternator rewinding services for various shipboard applications, including propulsion systems, generators, pumps, winches, and auxiliary equipment. Our work is carried out on-board or at our shore-based workshop, following IMO, class, and OEM standards to ensure reliability, efficiency, and longevity of the rewound units.

- Inspection and Fault Diagnosis

The motor or alternator is isolated, dismantled, and thoroughly inspected.

Visual checks, insulation resistance tests, and winding resistance tests are performed to determine the extent of damage.

Burnt, shorted, or open windings, and damaged insulation or bearings are identified and recorded. - Core Cleaning and Preparation

The stator or rotor core is cleaned of carbon deposits, oil, and debris using appropriate methods like baking, sandblasting, or chemical cleaning.

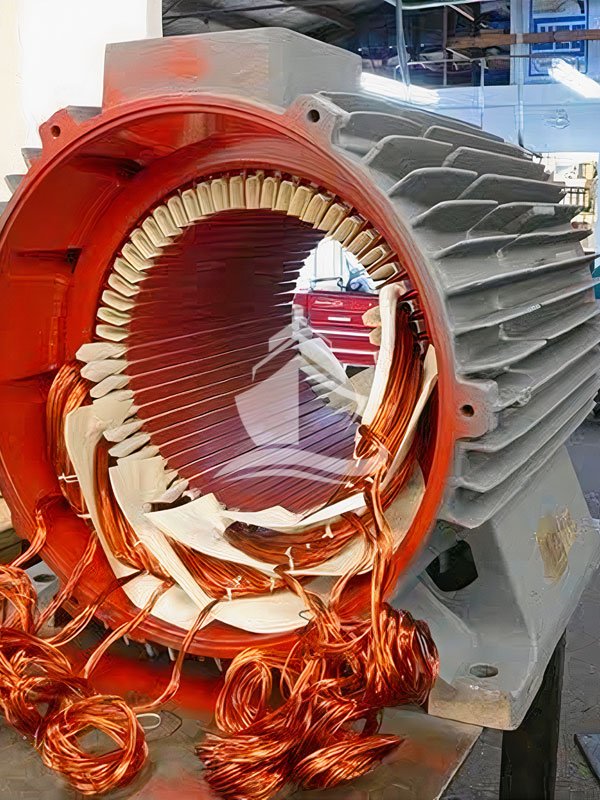

Lamination core integrity is checked to ensure no heat damage or distortion has occurred. - Rewinding Process

New winding wire (copper, Class H or F insulation grade) is selected as per original specifications.

Coils are formed, inserted into the slots, and insulated using varnish tapes and wedges.

Winding configuration, number of turns, and connections are carefully matched with the original design.

Connections are soldered and sealed, and the winding is vacuum-impregnated with insulating varnish for durability. - Assembly and Testing

After rewinding and curing, the motor/alternator is reassembled with new or reconditioned bearings and seals.

Dynamic balancing of the rotor is performed if necessary.

Final tests include:- Insulation resistance (IR) test

- High-voltage (HV) test

- No-load and load tests

- Vibration and temperature monitoring

- Documentation and Handover

A detailed service report is prepared, including test results, material specifications, and recommendations.

Class and shipboard approvals are obtained where required.

The rewound equipment is returned to service with full operational certification.

Meera Marine's rewinding services ensure shipboard motors and alternators are restored to OEM performance standards, extending equipment life and minimizing downtime at sea.